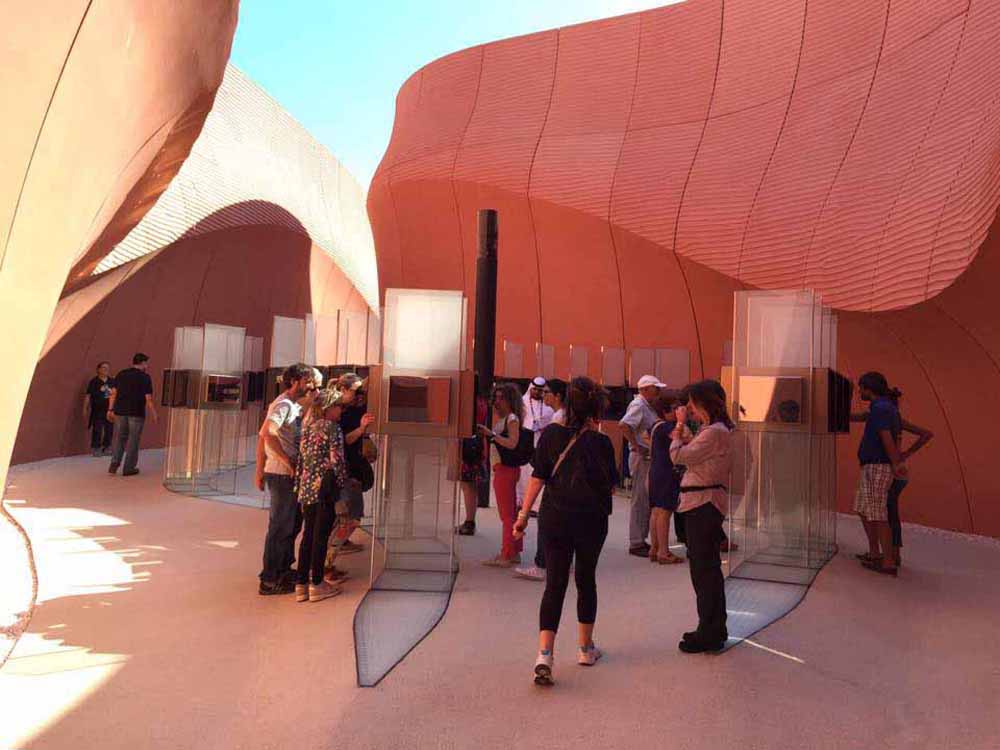

The complex task of building moving sand-dune walls at the UAE pavilion in Milan

By olya Wednesday, 05 August 2015 11:03 AM

Hundreds of intricate panels expertly made by engineers and workers in a factory in southern China were fitted together perfectly to build the giant, dune-inspired structure that is attracting thousands of people at the Milan Expo.

The sand-textured UAE pavilion walls were created using 330 moulds to replicate the patterns and ridges of dunes on to 903 panels made at a unit near Panyu city.

"People are touching it and can't believe it's concrete; they say it looks and feels like sand,” said Trevor Gregory, chairman of CanBuild, a Hong Kong-based architectural project management company. "An actual sand dune ridge moves up and down through the canyon so every panel is different. You not only see ripples, you also see splits in the ripples.”

Dunes in Al Ain were photographed to capture the vivid colours of the sand. A blend of yellow, orange and red pigments replicated vibrant shades on to the pavilion walls.

The CanBuild team constructed a mock-up last year based on the concept design mapped out by lead architects Foster + Partners. Production of glass-reinforced concrete (GRC) panels began in October last year and continued for four months.

A large area at the CanBuild yard was cleared to test sheets that varied in height from the size of a double-decker bus to a three-storey house.

"We had to make panels that connected together perfectly,” Mr Gregory said. "Nine panels together was the maximum we could do because that was over 200 square metres in a day. GRC is a special material with which you can do special things.

"It's a very strong material in terms of tensile strength. If that was normal concrete, the panels would have weighed 10 times more and would have been impossible to install. Plus, you would never get the fineness of detail.”

Working to the deadline was key, said John Bottomley, director of CanBuild. "We had up to 140 people working 24 hours a day, seven days a week. The most challenging task was to keep within the time frame due to the 330 different types of moulds that needed to be fabricated, coupled with the high degree of complexity.”

The final batch was shipped to Milan in March, in time for the expo opening on May 1. "The size was designed from the start to fit inside a container,” Mr Bottomley said. The pavilion also needed to be easily dismantled so it could be transported to its final home in Masdar City when the expo ends in November.

"GRC is robust, which is ideal for the desert environment and allows good ventilation,” said Gerard Evenden, senior executive partner at Foster + Partners. "This is essential in keeping the building cool in both climates.”

The project was a creative challenge for engineers usually involved in building homes and bridges. CanBuild has also worked on projects in the UAE including Masdar, the Zabeel Palace boundary wall and the Dubai Metro. "The UAE pavilion is really a construction project but it's quite unique because people are not treating it like a building but like a work of art,” Mr Gregory said. – The National –

Add new comment